When it comes to picking sustainable materials for a project, it’s not always straightforward. I’ve found it to be a process full of decisions—about where the materials come from, how they’re made, how they’ll be used, and even what happens to them when we’re done. It’s definitely not a one-size-fits-all situation.

What makes this journey exciting is that it’s not just about materials—it’s about creating a thoughtful balance. We’re talking about energy use, environmental responsibility, and even social and economic impacts. And in my experience, it’s this balance that really defines whether something is truly sustainable.

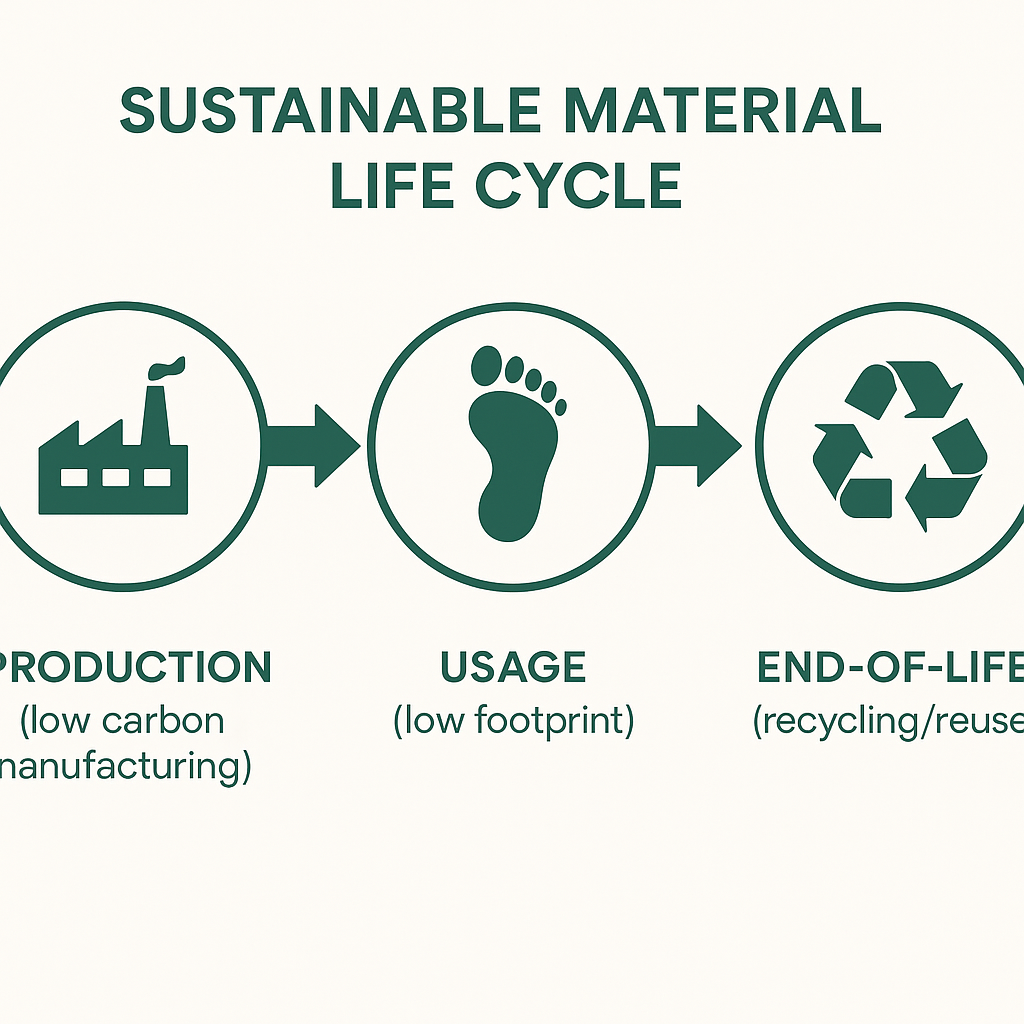

Understanding the Life Cycle Impact

One thing I’ve learned is that sustainability starts way before the material even reaches the site. You have to look at its entire life cycle:

- Production/Manufacturing – Is it made with minimal carbon emissions? That’s a huge deal.

- Usage Phase – Does it perform well without harming the environment? The lower the footprint, the better.

- After Use – Can it be reused or recycled easily? If yes, it takes pressure off our natural resources.

It’s all about asking the right questions and thinking ahead.

Why Local Context Matters So Much

I’ve worked in a few remote areas, and trust me, the local context can make or break your material choices. Sometimes, certain materials just aren’t available—or their transport footprint makes them less sustainable than you’d think.

That’s why I believe in embracing local solutions. Often, local materials have been used for generations in traditional ways. With a little creativity and some modern technology, those time-tested techniques can be enhanced to make them even more durable and efficient. It’s incredibly satisfying to see old and new come together in a sustainable way.

Local Sourcing: It’s More Than Convenience

At first, I used to think that sourcing locally was just about convenience. But the more I’ve worked with sustainable builds, the more I’ve realized: local sourcing is a game-changer.

Less transportation means fewer emissions. Plus, it keeps the project more agile and responsive. And honestly, there’s something fulfilling about supporting local suppliers and knowing the material’s full story.

The Cost Question: Is It Worth It?

Yes, sustainable materials can cost more upfront—I won’t deny that. But over time, I’ve seen how they pay for themselves. Lower energy bills, less maintenance, and better overall performance make a huge difference in the long run.

It’s like an investment—not just in the project, but in the planet and future generations. And that shift in perspective really changes the way you approach every decision.

Conclusion: It’s a Personal Commitment

For me, choosing sustainable materials isn’t just about ticking a box—it’s a commitment to building responsibly. It’s about being mindful of where things come from, how they’re used, and what kind of future they leave behind.

The process takes time, effort, and a lot of learning—but it’s incredibly rewarding. When you choose materials with care and understanding, you’re not just building something sustainable—you’re building something meaningful.